Hot Water Boiler

Capacity:1400-80000KW(1.2-68 Million Kcal)

Applicable Fuels: Gas,Biomass pellets,Electricity,etc.

Applicable Fuels: Gas,Biomass pellets,Electricity,etc.

Application Industries: Heating,Shool,Hotel,ect.

Application Industries: Heating,Shool,Hotel,ect.

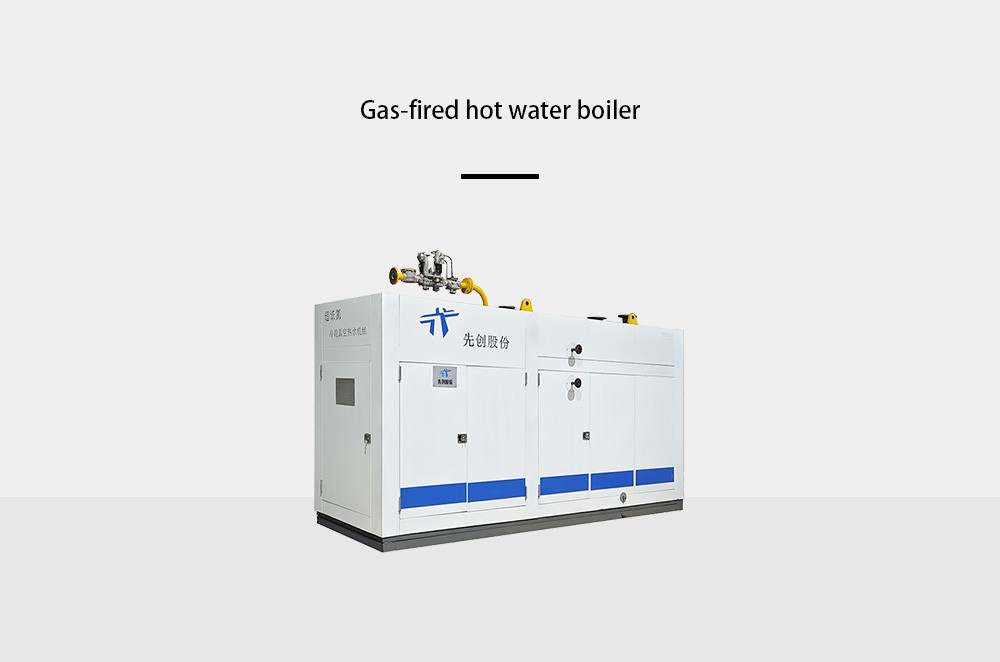

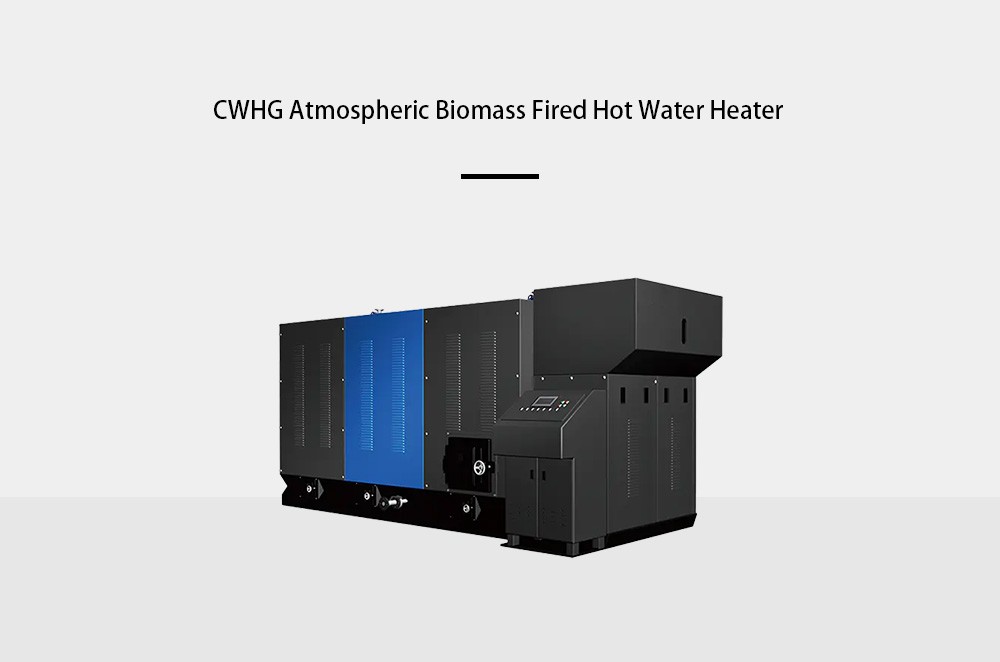

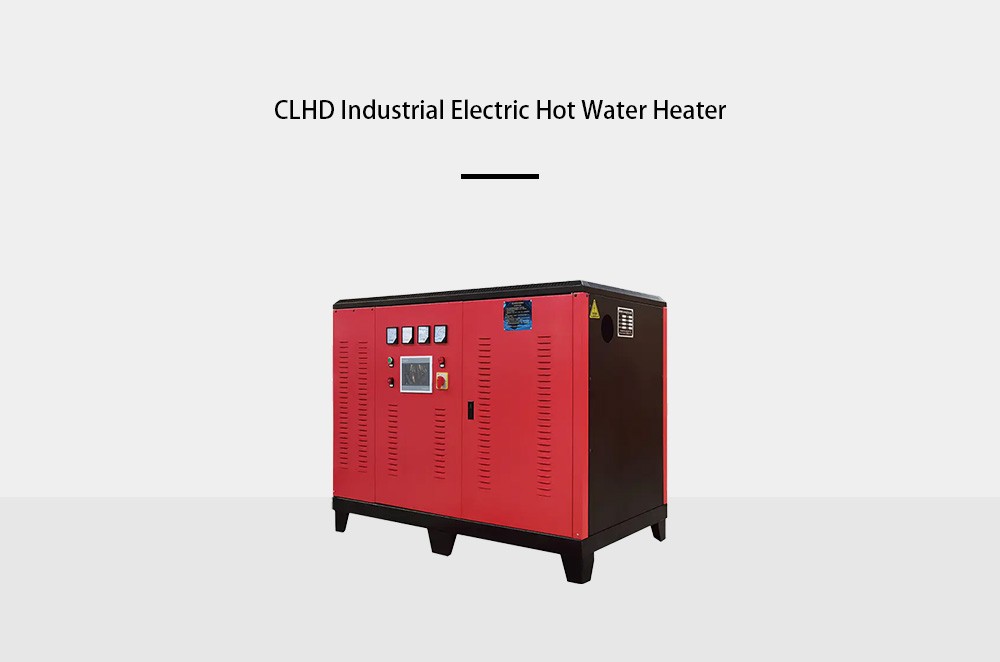

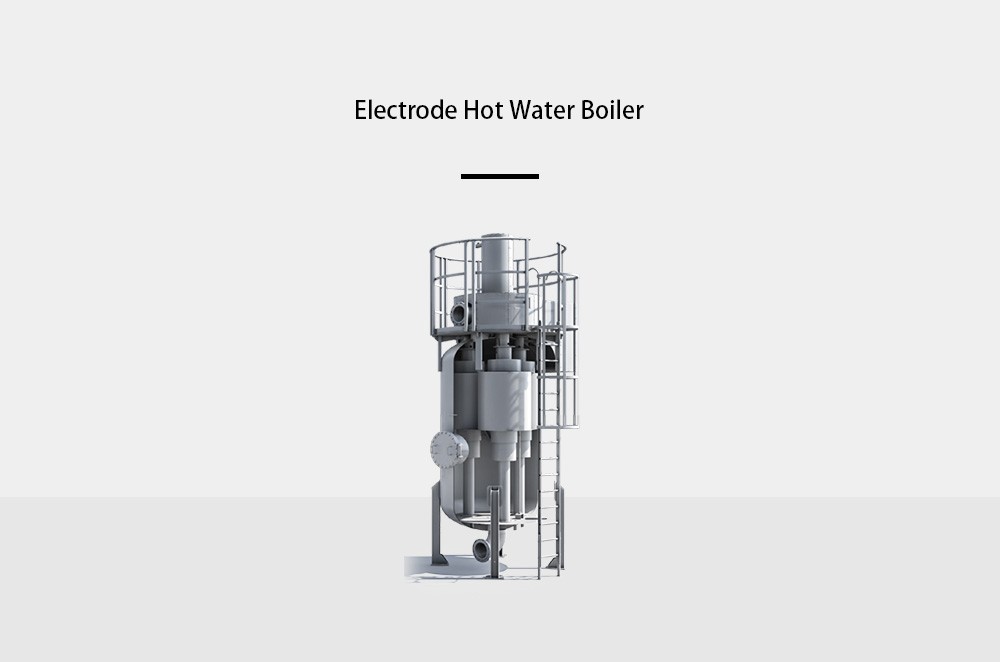

The model range of Xian Chuang hot water boilers includes Gas-fired hot water boiler,CWHG atmospheric biomass fired hot water boiler,Arpany High-Voltage electrode hot water boiler,CLHD industrial electric hot water heater.

For more information about this boiler model,please contact us !

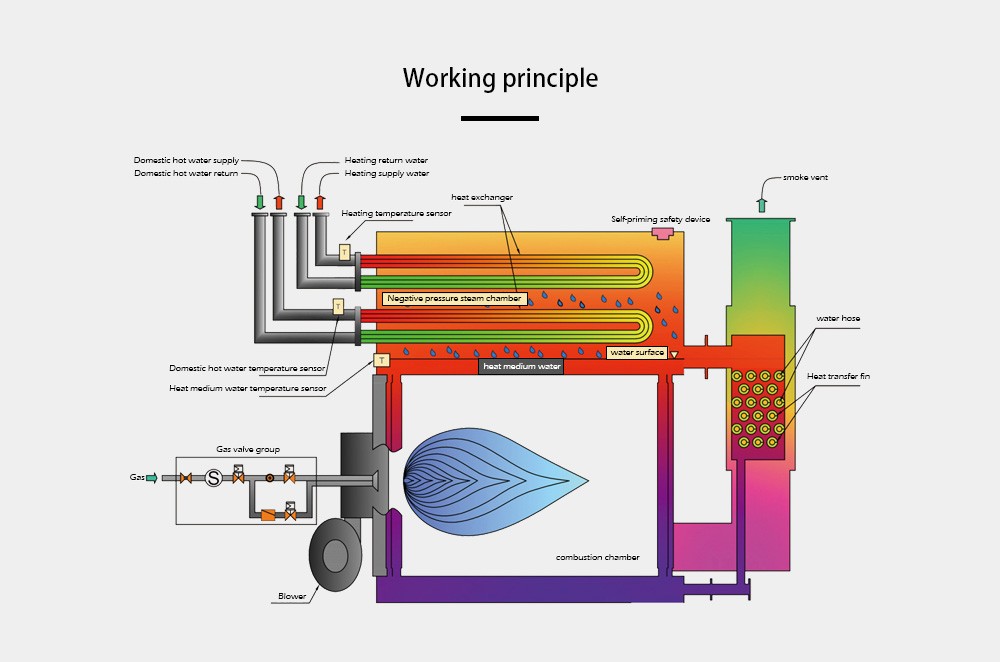

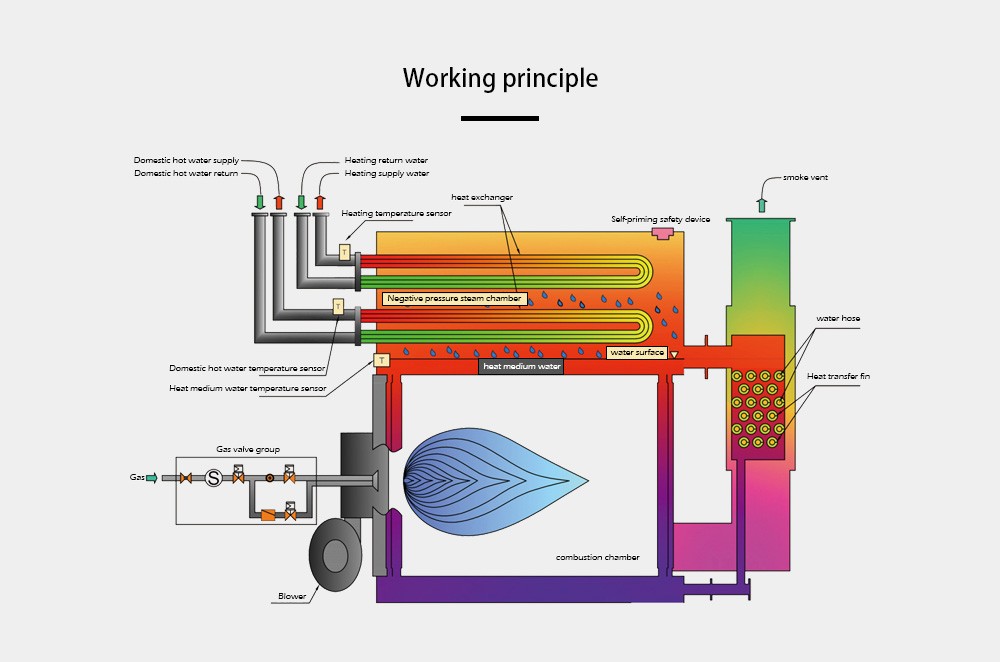

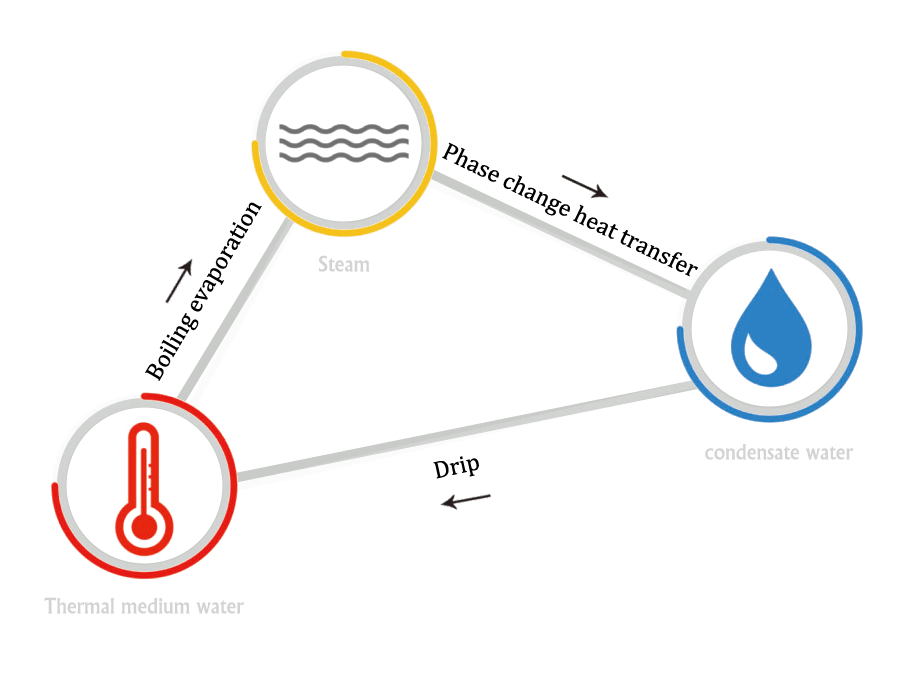

| Product Introduction A hot water boiler is a thermal energy device that heats water to specified temperatures by combusting fuels or using electric energy, delivering heated water for end-use applications. Its primary function is to provide a stable heat source for heating systems, domestic hot water, or industrial processes, operating as either a pressurized or atmospheric vessel. |

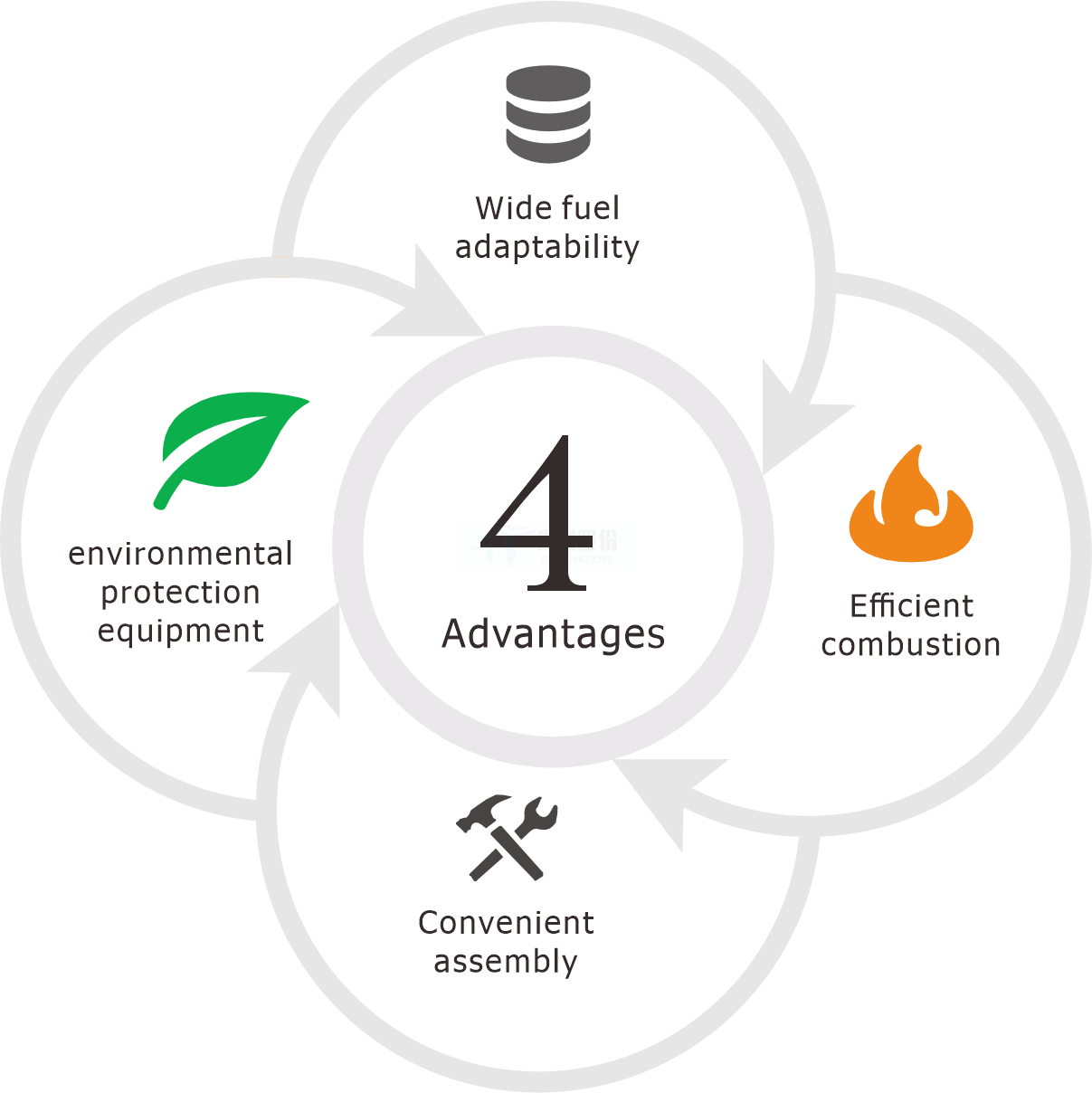

Product advantages XianChuang integrates gas, coal, biomass, and electric heating into one versatile boiler system. Featuring the world's most advanced water-cooled fully premixed combustion technology, it achieves ultra-high energy efficiency while effectively suppressing NOx formation. With a remarkable thermal efficiency exceeding 99.8%, our hot water boiler reaches 100% load capacity in just 30 seconds - faster than boiling water on your induction cooker! |  |

| Boiler model | CWHL2.8-85/60-S | CWHL3.5-85/60-S | CWHL4.2-85/60-S | CWHL4.9-85/60-S | CWHL5.6-85/60-S | CWHL7.0-85/60-S |

| Thermal power (MW) | 2.8 | 3.5 | 4.2 | 4.9 | 5.6 | 7.0 |

| Heat generation (10000 kcal) | 240 | 300 | 360 | 420 | 480 | 600 |

| Inlet and outlet diameter | 150 | 200 | 250 | 250 | 250 | 300 |

| Maximum fuel consumption(kg/h) | 600 | 750 | 900 | 1050 | 1200 | 1500 |

| Equipment size(mm) | 5000x2050x2700 | 6000X2150X2800 | 6500x2400x2950 | 7000x2400X3000 | 7500X2600X3200 | 9500X3400X3600 |

| Equipment weight(T) | 10.5 | 12.35 | 15.5 | 19.5 | 22.8 | 26.5 |

Note: This table displays parameters for CWHG atmospheric biomass fired hot water heater. For other models of thermal oil boilers, please navigate to the corresponding webpage or contact customer service.

Leave your email and we’ll send you tailored boiler solutions, case studies, and pricing info within 24h.