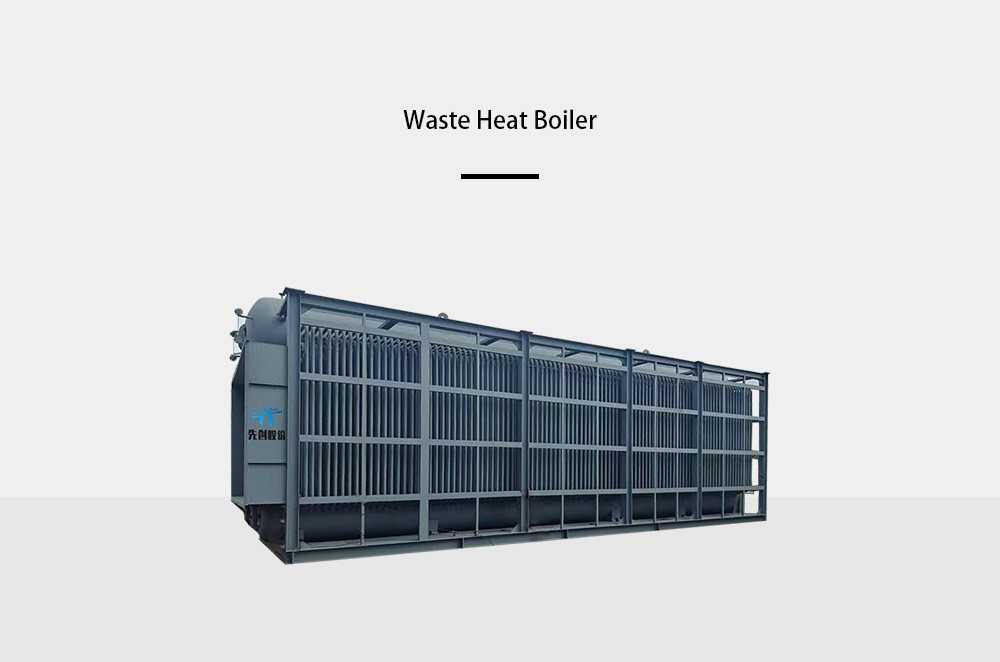

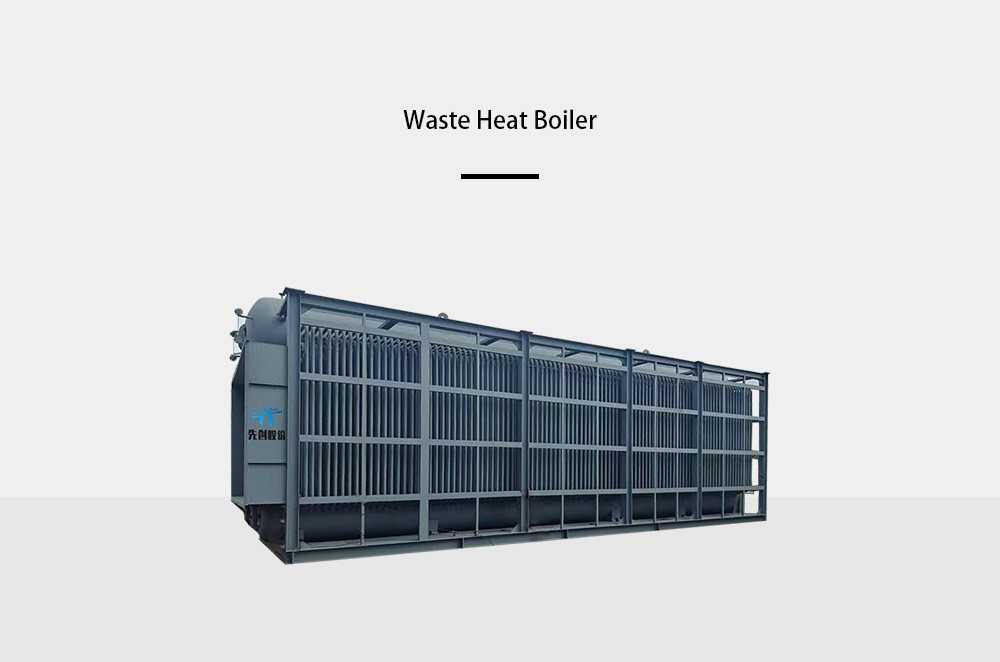

Waste Heat Boiler

Capacity: ≥3 t/h

Applicable Fuels: Waste heat, waste gas, waste liquid, etc.

Applicable Fuels: Waste heat, waste gas, waste liquid, etc.

Application Industries: Glass factory, steel plant, chemical plant, etc.

Application Industries: Glass factory, steel plant, chemical plant, etc.

Xianchuang's waste heat boilers include cement kiln waste heat boilers, glass melting furnace waste heat boilers, steel smelting waste heat boilers, chemical industry three waste waste heat boilers, etc.

For more information about this boiler model, please contact us!

① Save energy costs By recovering heat from exhaust gases, fuel demand is reduced and energy consumption is lowered. ② Improve thermal efficiency Waste heat from exhaust gases can be used for heating or power generation, significantly improving overall thermal energy efficiency. ③ Environmental protection and emission reduction Effectively reduces exhaust gas emissions and pollution. ④ Lower operating costs Reduces fuel consumption and energy waste, thereby lowering long-term operating costs. |  |

| Model | Rated evaporation capacity (t/h) | Rated steam pressure(Mpa) |

| QC30/800-10-1.25 | 10 | 1.25 |

| QC30/850-12-1.6 | 12 | 1.6 |

| QC30/850-18-1.6 | 18 | 1.6 |

| QC30/850-20-1.6 | 20 | 1.6 |

| QC30/900-25-1.6 | 25 | 1.6 |

| QC30/1100-30-1.6 | 30 | 1.6 |

Leave your email and we’ll send you tailored boiler solutions, case studies, and pricing info within 24h.