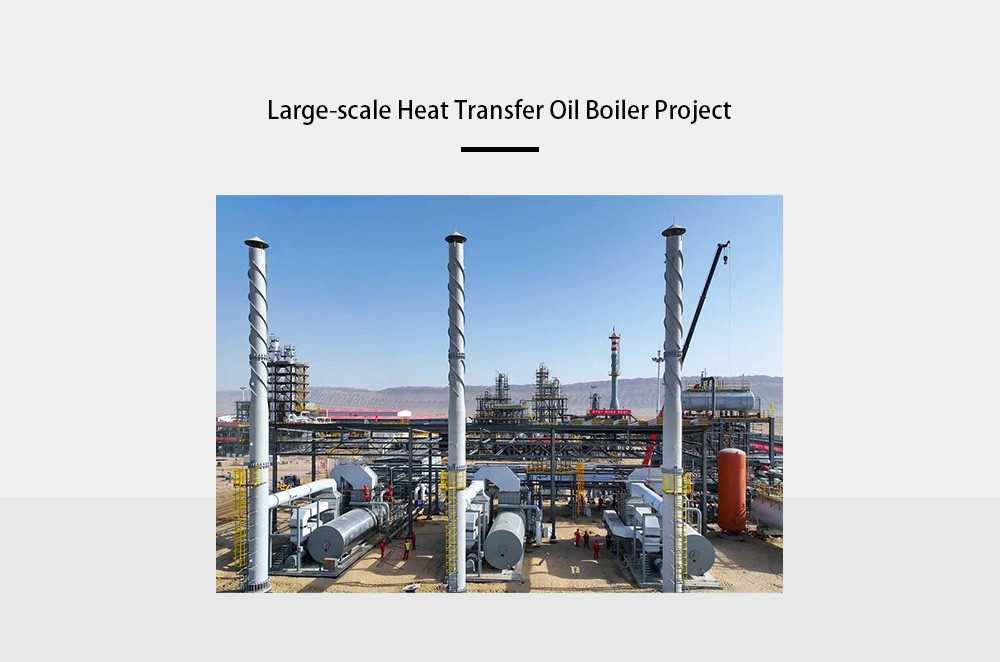

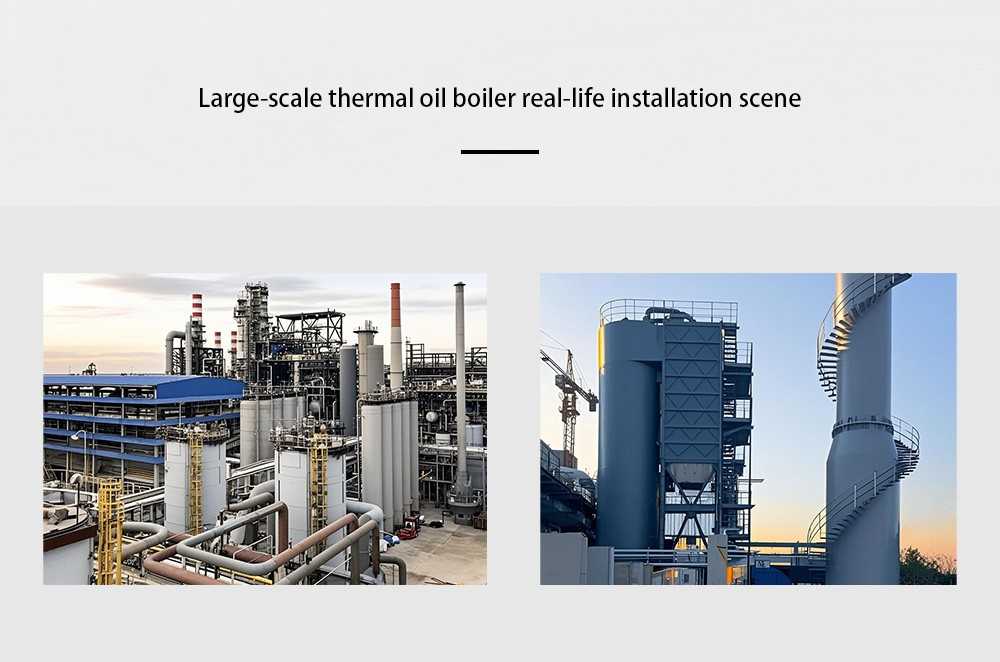

Thermal Oil Boiler

Capacity: 1400-29200KW (1.2-25 Million Kcal)

Applicable Fuels: Gas, Oil, Coal, Biomass, Electric

Applicable Fuels: Gas, Oil, Coal, Biomass, Electric

![]()

Application Industries: Petroleum, Chemical, Pharmaceutical,etc.

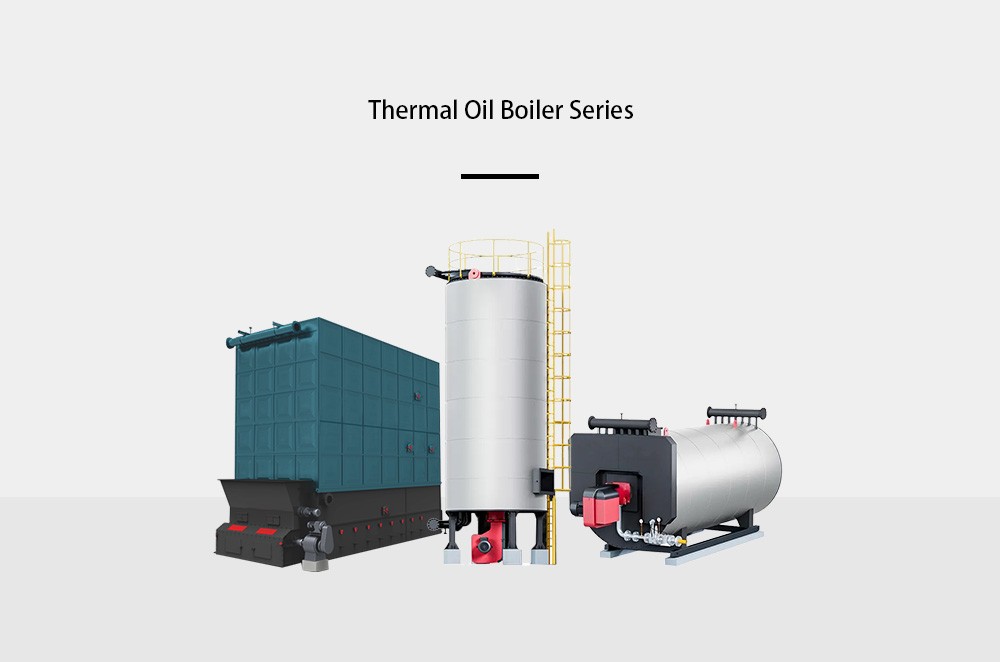

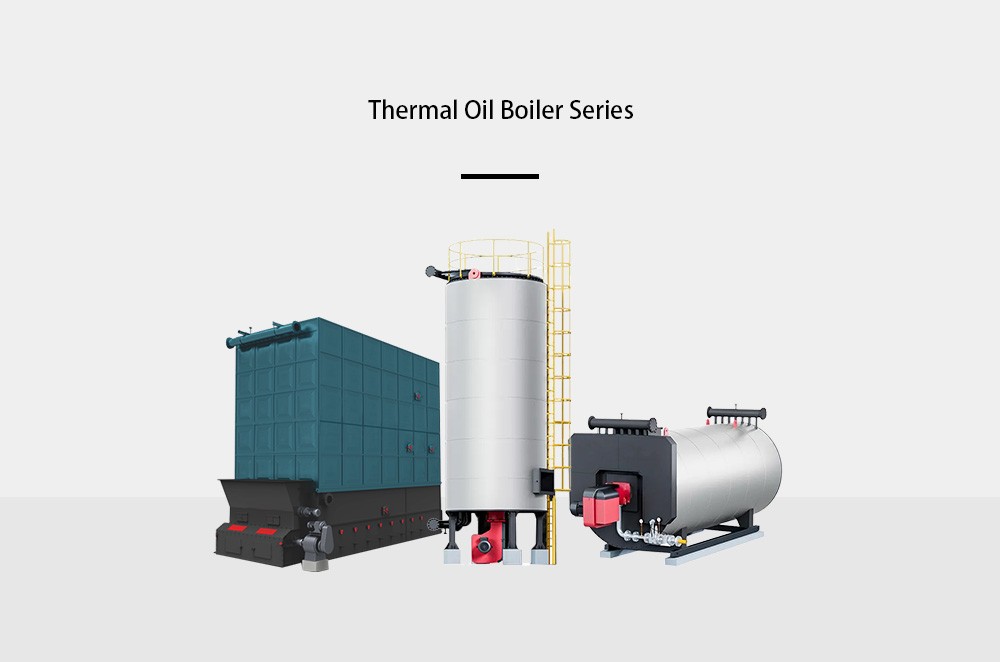

The model range of Xian Chuang thermal oil boilers includes YY(Q)L series vertical oil/gas-fired thermal oil boilers, YQ(Y)W series horizontal oil/gas-fired thermal oil boilers, YLW series biomass-fired thermal oil boilers, YLW series coal-fired thermal oil boilers, and electric heating thermal oil boilers.

For more information about this boiler model, please contact us !

A thermal oil boiler is an industrial heating device that utilizes thermal oil (heat transfer fluid) as a heat-conducting medium. It transfers thermal energy to the thermal oil either through fuel combustion or electric heating methods, then delivers the heat to heat-consuming equipment via a high-temperature oil circulation system, thereby achieving indirect heating.

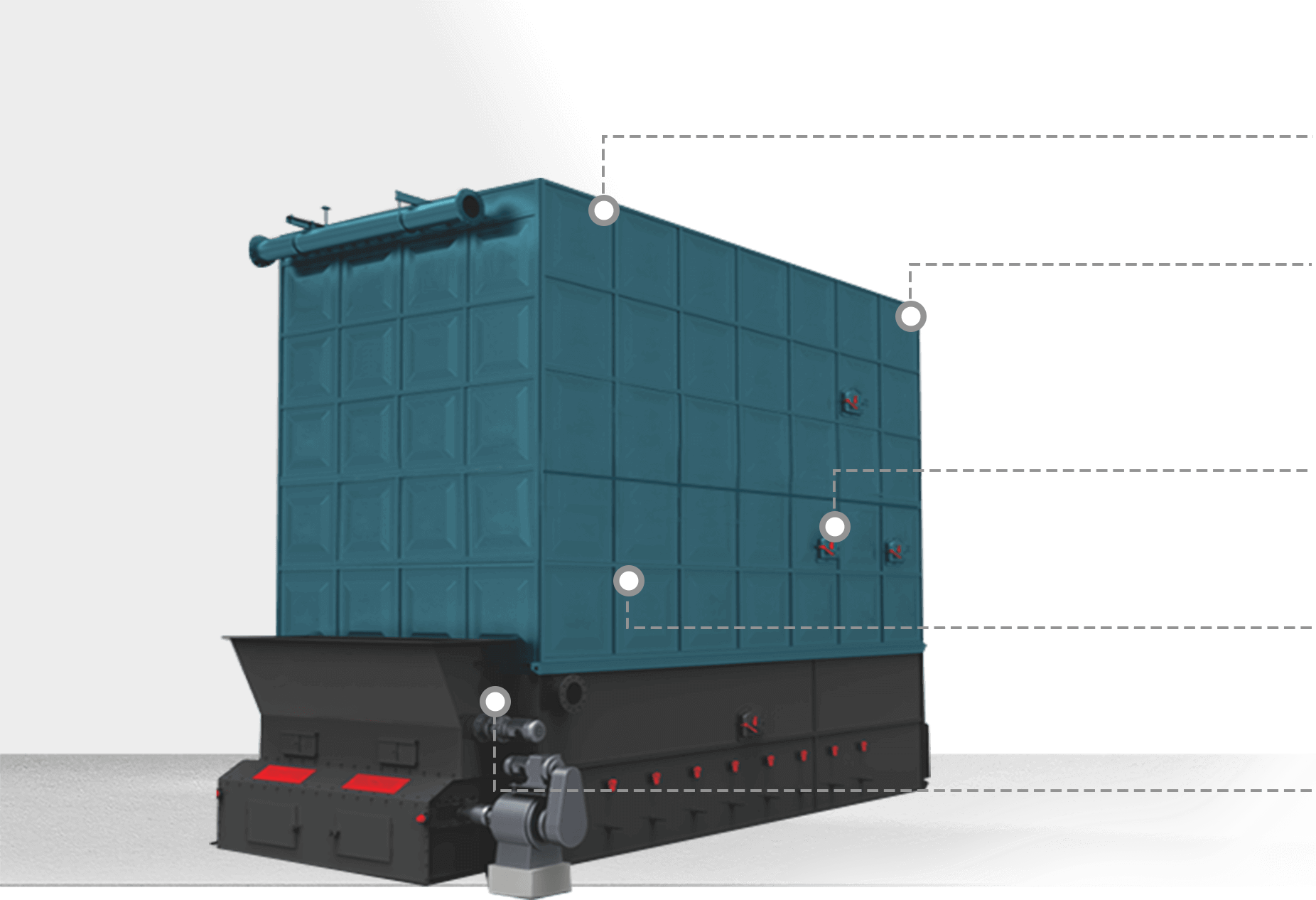

| ① Multi-circuit coil The flue gas heating surface is sufficient, and the contact time is long. |

② Partition wall Good flue gas isolation effect, reducing heat loss. | |

③ Ash removal door Convenient for personnel to perform maintenance, operation, and cleaning. | |

| ④ Combustion chamber Wide fuel adaptability, suitable for bituminous coal, anthracite, biomass pellets, etc | |

⑤ Speed control box Reasonable speed designed according to fuel characteristics to ensure complete combustion. | |

| Note:This boiler body structure diagram uses the YLW biomass thermal oil boiler as an example. |

① Patented innovative technology Patented variable flow rate technology achieves thermal efficiency of over 95%. ② Intelligent Maintenance System The intelligent warning system reduces losses from unplanned downtime, enabling unmanned operation. ③ Environmental Protection and Low Emission Technology Utilising comprehensive low nitrogen oxide control technology, it meets environmental requirements in different regions. ④ Space-Saving Design The boiler can be manufactured as a single unit or in separate sections, significantly reducing transportation costs. |

|

| Model | YLW-1400S | YLW-1800S | YLW-2400S | YLW-2800S | YLW-3500S | YLW-4200S | YLW-4600S | |

| Rated thermal power | MW | 1.4 | 1.8 | 2.4 | 2.8 | 3.5 | 4.2 | 4.6 |

| x10⁴ kal/h | 120 | 160 | 160 | 240 | 240 | 360 | 400 | |

| Rated outlet temperature | (℃) | 320 | 320 | 320 | 320 | 320 | 320 | 320 |

| Rated working pressure | (MPA) | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 |

| Heat Efficiency | (≥%) | ≥80 | ≥80 | ≥80 | ≥80 | ≥80 | ≥80 | ≥80 |

| System installed capacity | (KW) | 55 | 63 | 76 | 86 | 105 | 125 | 155 |

| Min. transport dimension | Length(MM) | 5000 | 5600 | 6500 | 6500 | 7500 | 7400 | 8000 |

| Width(MM) | 2250 | 2250 | 2500 | 2550 | 2550 | 2870 | 2820 | |

| Height(MM) | 2450 | 2750 | 2800 | 3200 | 3200 | 3300 | 3350 | |

| Max. transportation weight | (KG) | 11000 | 12700 | 13500 | 14500 | 16500 | 25500 | 29000 |

| Model | YLW-6000S | YLW-7000S | YLW-8200S | YLW-9400S | YLW-10500S | YLW-12000S | YLW-14000S | |

| Rated thermal power | MW | 6 | 7 | 8.2 | 9.4 | 1.5 | 12 | 14 |

| x10⁴ kal/h | 500 | 600 | 700 | 800 | 900 | 1000 | 1200 | |

| Rated outlet temperature | (℃) | 320 | 320 | 320 | 320 | 320 | 320 | 320 |

| Rated working pressure | (MPA) | 1 | 1 | 1 | 10 | 1 | 1 | 1 |

| Heat Efficiency | (≥%) | ≥80 | ≥80 | ≥80 | ≥80 | ≥80 | ≥80 | ≥80 |

| System installed capacity | (KW) | 170 | 193 | 150 | 160 | 160 | 260 | 320 |

| Min. transport dimension | Length(MM) | 8320 | 9000 | 9760 | 9760 | 10500 | 11200 | 10500 |

| Width(MM) | 3330 | 3330 | 3270 | 3500 | 3500 | 3560 | 4000 | |

| Height(MM) | 3250 | 3350 | 4010 | 4010 | 4010 | 4010 | 3500 | |

| Max. transportation weight | (KG) | 33500 | 36000 | 35000 | 24800 | 25000 | 27500 | 31000 |

Note: This table displays parameters for YLW Biomass Fired Thermal Oil Boiler. For other models of thermal oil boilers, please navigate to the corresponding webpage or contact customer service.

Leave your email and we’ll send you tailored boiler solutions, case studies, and pricing info within 24h.