Capacity:1400-14000 KW

Working Pressure: 0.8-1MPa

Working Pressure: 0.8-1MPa

Thermal Efficiency: ≥95%

Thermal Efficiency: ≥95%

Applicable Fuels: Gas,diesel,etc.

Applicable Fuels: Gas,diesel,etc.

Application Industries: Chemical, fiber,wood processing,etc.

Application Industries: Chemical, fiber,wood processing,etc.

The YQ(Y)W Gas/Oil Fired Horizontal Thermal oil boiler adopts a three-way circular coil structure, the end of the coil adopts conical coil, which effectively protects the furnace wall

at the end of the boiler, and is equipped with advanced combustion device, which has good energy-saving and environmental protection performance. The furnace type has the

characteristics of wide fuel adaptability, low pressure and high temperature, safety and high efficiency, the thermal efficiency is up to more than 95%, and the perfect automatic

control system can be unattended.

| Model | Rated Power (KW) | Rated thermal power (x10⁴ kcal/h) | Design Oil Temperature(≤℃) | Rated Working Pressure (MPa) | Heat Efficiency (≥%) | System Power Supply (KW) | MAX Transport size (m)(L×W×H) |

| YY(Q)W-1400 Y(Q) | 1400 | 120 | 320 | 0.8 | 95 | 35 | 4.3×2.0×2.6 |

| YY(Q)W-1800 Y(Q) | 1800 | 160 | 320 | 0.8 | 95 | 56 | 4.9×2.2×2.6 |

| YY(Q)W-2400 Y(Q) | 2400 | 200 | 320 | 0.8 | 95 | 56 | 5.3×2.5×3.0 |

| YY(Q)W-2800 Y(Q) | 2800 | 240 | 320 | 0.8 | 95 | 66 | 6.1×2.5×3.0 |

| YY(Q)W-3500 Y(Q) | 3500 | 300 | 320 | 0.8 | 95 | 75 | 6.7×2.6×3.0 |

| YY(Q)W-4200Q | 4200 | 360 | 320 | 0.8 | 95 | 95 | 6.9×2.7×3.2 |

| YY(Q)W-4600Q | 4600 | 400 | 320 | 0.8 | 95 | 95 | 7.0×2.9×3.4 |

| YY(Q)W-6000Q | 6000 | 500 | 320 | 0.8 | 95 | 140 | 7.2×3.3×3.9 |

| YY(Q)W-7000Q | 7000 | 600 | 320 | 0.8 | 95 | 140 | 8.0×3.6×4.0 |

| YY(Q)W-8200Q | 8200 | 700 | 320 | 0.8 | 95 | 140 | 8.5×3.7×4.0 |

| YY(Q)W-9400Q | 9400 | 800 | 320 | 1 | 95 | 200 | 9.5×3.8×4.0 |

| YY(Q)W-10500Q | 10500 | 900 | 320 | 1 | 95 | 200 | 10.5×3.8×4.0 |

| YY(Q)W-12000Q | 12000 | 1000 | 320 | 1 | 95 | 240 | 12.4×3.8×4.0 |

| YY(Q)W-14000Q | 14000 | 1200 | 320 | 1 | 95 | 300 | 13.5.×4.0×4.2 |

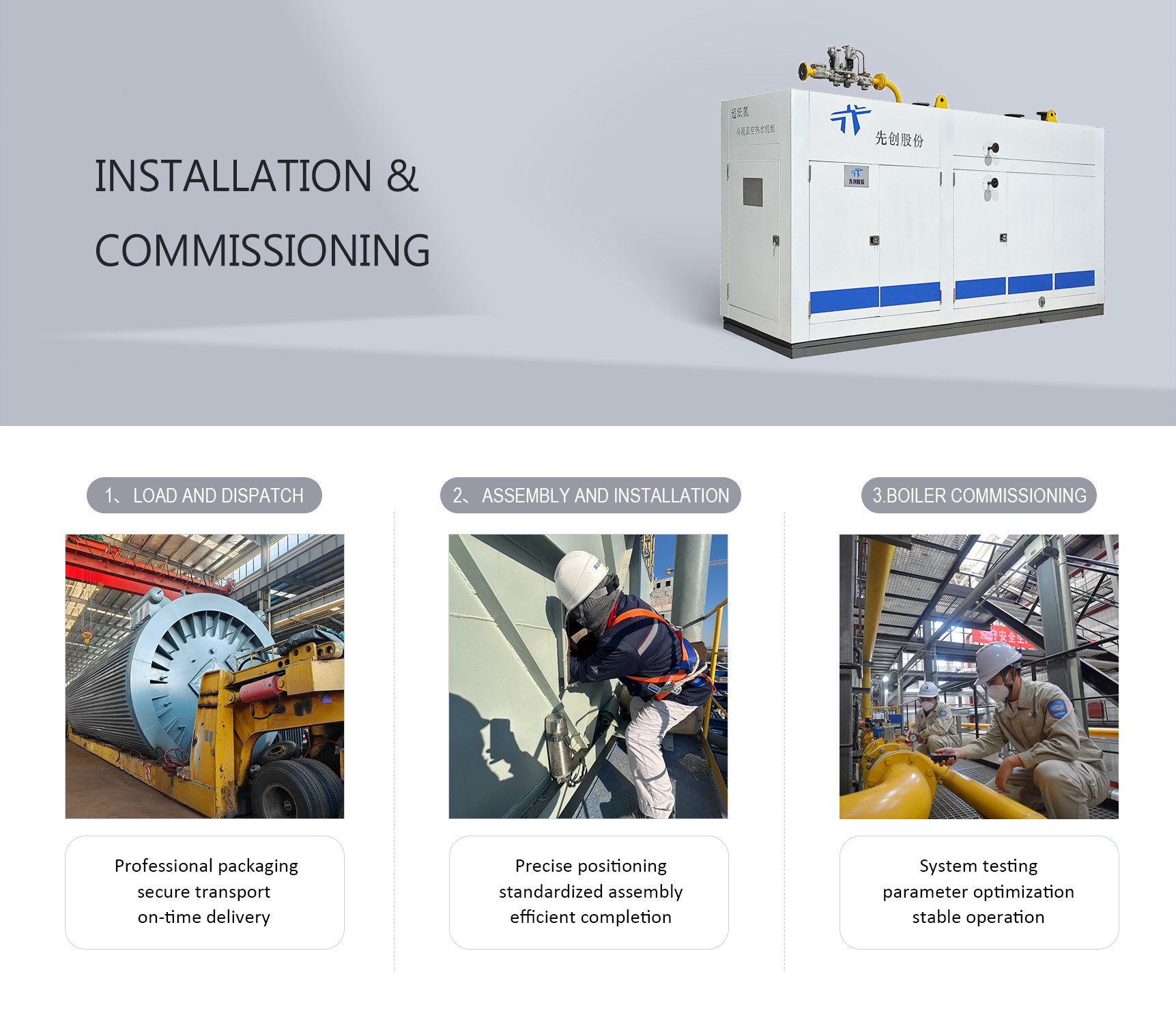

1. What are your advantages in boiler production?

With over 20 years of industry expertise, XianChuang operates cutting-edge facilities, including smart factories and W11S-80*2500 CNC plate rolling machines. We hold comprehensive and rare certifications, enabling us to execute large-scale EPC, PPP, and BOT projects.

2. How much can your equipment reduce operational costs compared to traditional boilers?

We optimize costs from multiple dimensions, including fuel, transportation, labor, long - term investment, and other implicit costs. This approach helps customers achieve significant cost savings and efficiency improvements, and ensures long - term reliable operation of the equipment. The specific cost - reduction figures can be calculated based on customized solutions for each project.

3. What is the typical thermal efficiency of your boilers? How to improve it?

Standard models achieve 85–95% efficiency, while condensing steam boilers reach 105%. Key improvements include regular descaling, optimal fuel combustion, precise burner adjustments, and pipeline insulation.

4.Who are your key clients?

We have established partnerships with many industry - leading enterprises, including the largest domestic chemical fiber company, renowned global Fortune 500 companies, as well as well - known brands such as Inner Mongolia Yili Industrial Group Co., Ltd. and Zhejiang Sanmei Chemical Co., Ltd. As one of the drafters of industry guiding opinions, our company has maintained the top position in sales performance for consecutive years, occupying a market share of over 90% in our specific business segment.

5.How long is the repair response time after a boiler breaks down?

We offer 24 - hour after - sales response service. Professional personnel will be dispatched to the site for handling to resolve the issues promptly.

For all inquiries, please fill in the form below (* are required) to send us a brief message, and we will get back to you as soon as possible.